Phone

All of our motors have wet stator and rotor. It is designed to work in water. Lubrication and cooling of radial and axial bearings are provided by water.

In our company;

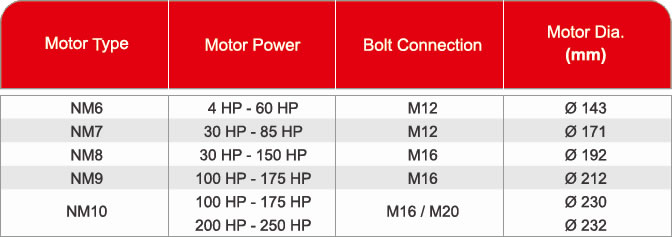

• 5",6",7",8",9",10" and 12” types,

• From 3 kW to 300 kW power,

• At 2 poles 50 Hz (2900 rpm) and 2 poles 60 Hz (3450 rpm) frequencies and speeds,

• 3 phases 380 - 415 Volt (50Hz) with 3 phases 230 - 460 Volt (60 Hz) voltage range,

• Rewindable feature,

• Submersible motors operating at a maximum water temperature of 30 °C are produced.(Optional water temperature 70 ° C).

All our motors have been subjected to the required tests according to the definitions of the standards before shipment. In the products; "Superior Technology and Low Energy Consumption" are given importance.

1-) STATOR:

It is the non-moving part of the submersible motor. It consists of pressing siliconized steel sheets. Three-phase rotating magnetic field windings are present here. The motor shell is made of AISI 304 material.

2-) ROTOR:

It is the part where the rotating and mechanical energy of the submersible motor is taken. It consists of siliconized steel sheet package and rotor shaft which passes through the middle of this package. Copper rods are placed in the grooves around the rotor and short circuit by copper rings.

The rotor shaft is made of CK 45 material with AISI 304 shaft end.

BEARINGS:

The radial and axial thrust bearings used in our engines are made of special carbon composition which is resistant to abrasion and impact. Rotor shaft bushings are made of hardchrome plated material.

The axial loads in the downward direction are balanced by aspecial bearing of "Mitchell" type, which is made up of self-tapping. All of these bearings are designed to be lubricated and cooled by water.

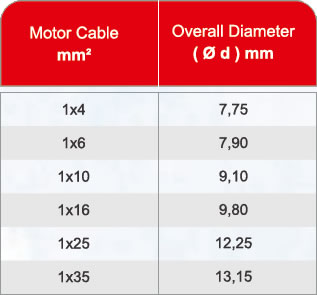

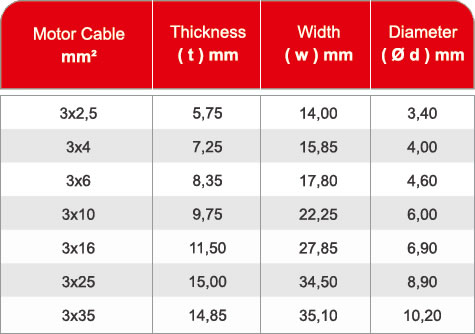

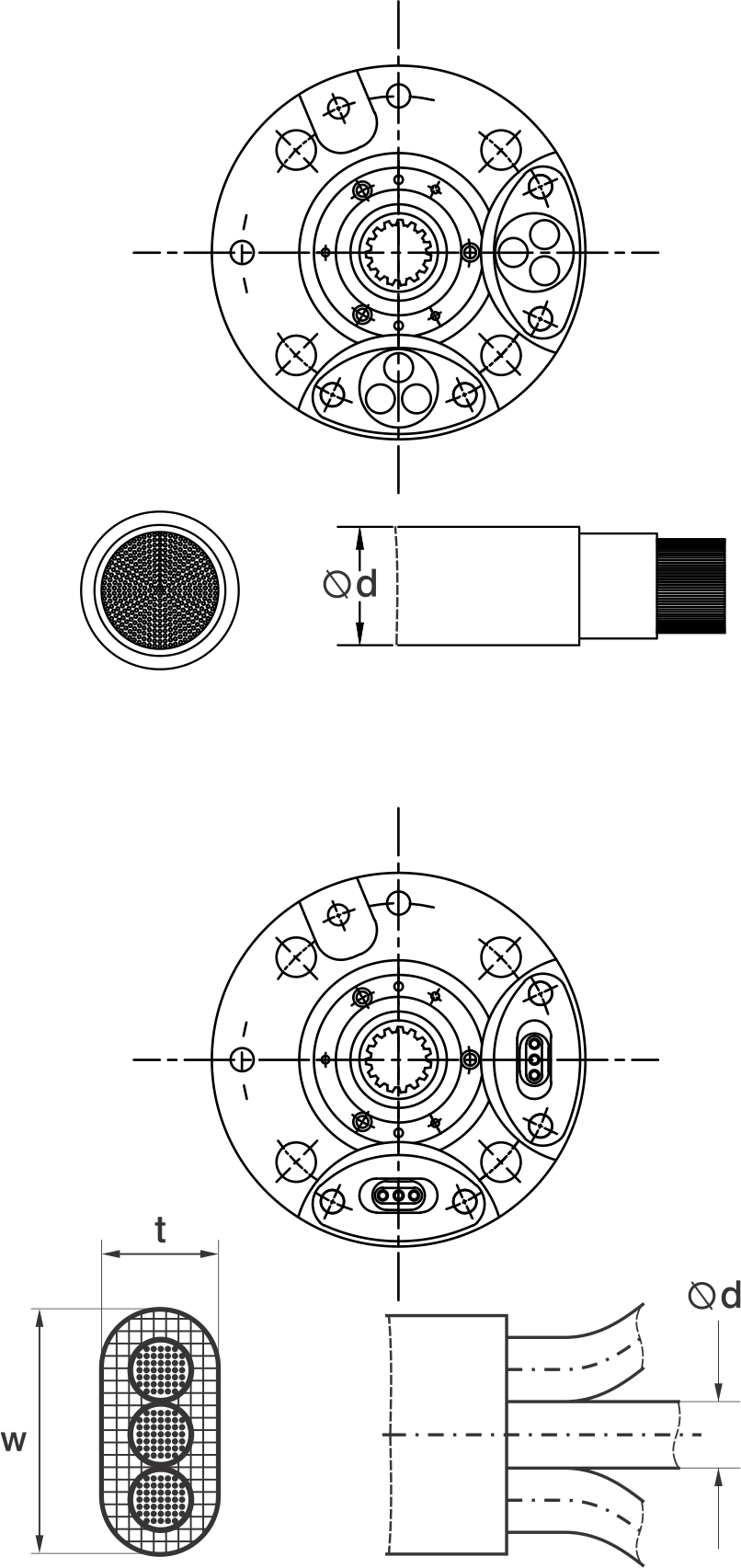

ELECTRIC CABLE:

Cable suitable for working underwater.

STARTING:

D.O.L. starting 4 HP - 20 HP, ñ / A between 25 HP - 250 HP. Motors can designed suitable for D.O.L. and various voltage and frequency depending on demand.

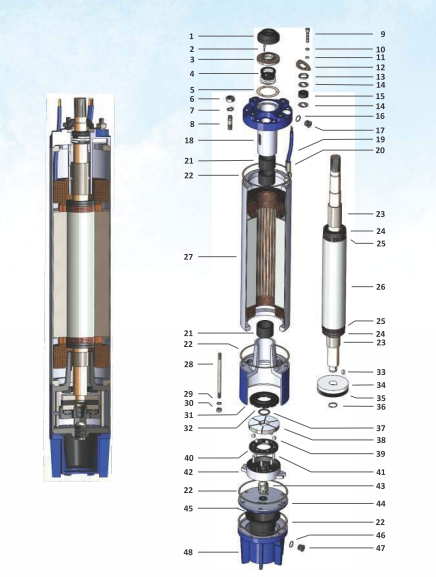

| Part Name | Material | |

|---|---|---|

| 1 | Slinger (Sand Guard) | RUBBER (EPDM) |

| 2 | Mechanical Seal Coverin lmbus Screw | AISI 304 |

| 3 | Mechanical Seal Cover | AISI 420 |

| 4 | Mechanical Seal | SERAMIC - CARBON |

| 5 | Mechanical Seal Klinger Gasket | PAPER |

| 6 | Motor-Pump Locking Nut | AISI 304 |

| 7 | Motor-Pump Locking Washer | AISI 304 |

| 8 | Motor-Pump Assembly Studs | AISI 304 |

| 9 | Upper Bearing Body Screw | AISI 304 |

| 10 | lmbus Screw O-ring | RUBBER (NBR) |

| 11 | lmbus Screw Washer | COPPER |

| 12 | Cable Cover | AISI 304 |

| 13 | Cable-Press Part | THERMOPLASTIC |

| 14 | Cable-Press Washer | AISI 304 |

| 15 | Gland | RUBBER (EPDM) |

| 16 | Plug O-ring | RUBBER (NBR) |

| 17 | Plug | AISI 304 |

| 18 | Upper Bearing Body | CASTIRON (GG20) |

| 19 | Electric Cable | COPPER |

| 20 | Plastic Cable Holder (Glove Type) | RUBBER (EPDM) |

| Part Name | Material | |

|---|---|---|

| 21 | Radial Carbon Bearing | CARBON |

| 22 | Klinger Gasket | PAPER |

| 23 | Rotor Shaft Bushing | CHROME COATED ST 52 |

| 24 | Rotor Balance Ring | ST 37 |

| 25 | Short Circuit Ring | COPPER |

| 26 | Rotor | SILICA SHEET / STEEL SHAFT / COPPER |

| 27 | CoilStator | SILICA SHEET / STEEL SHAFT / COPPER |

| 28 | Tie Rod | AISI 304 |

| 29 | Sealing O-ring | RUBBER (NBR90) + STEEL |

| 30 | Lower Cover Nut | AISI 304 |

| 31 | Lower Bearing Body | CASTIRON (GG20) |

| 32 | Counter-thrust Sliding Block | RUBBER (EPDM) |

| 33 | Thrust Bearing Wedge | AISI 304 |

| 34 | Thrust Sliding | AISI 420 |

| Part Name | Material | |

|---|---|---|

| 35 | Thrust Disc | CARBON |

| 36 | Seeger Ring | ST 52 |

| 37 | Mitchell Thrust Bearing 0-ring | RUBBER (NBR) |

| 38 | Mitchell Thrust Bearing Sliding Blocks | AISI 420 |

| 39 | Mitchell Thrust Bearing Balls | AISI 304 |

| 40 | Mitchell Thrust Bearing Ball Centering | ST 37 |

| 41 | Mitchell Thrust Bearing Pins | AISI 304 |

| 42 | Mitchell Thrust Bearing Body | CASTIRON (GG20) |

| 43 | Motor Adjustment Screw | AISI 420 |

| 44 | Membrane Flange | CASTIRON (GG20) |

| 45 | Membrane | RUBBER (EPDM) |

| 46 | Lower Plug 0-ring | RUBBER (NBR) |

| 47 | Lower Plug | AISI 304 |

| 48 | Membrane Body | CASTIRON (GG20) |