Phone

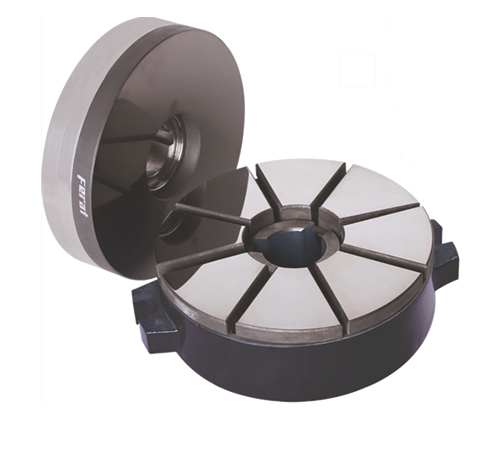

Heavy duty bearings provide the option to rotate two - way, have the capacity to carry high thrust load.

Heavy duty bearings provide the option to rotate two - way, have the capacity to carry high thrust load. Prevents entry of sand and other particles into motor. Keeps high durability for bearings.

Prevents entry of sand and other particles into motor. Keeps high durability for bearings. Membrane minimizes the expansion pressure that is caused by heating of cooling waters inside the motor.

Membrane minimizes the expansion pressure that is caused by heating of cooling waters inside the motor. Standard shaft height can be precisely adjusted by the adjustment screw on the thrust bearing base.

Standard shaft height can be precisely adjusted by the adjustment screw on the thrust bearing base.

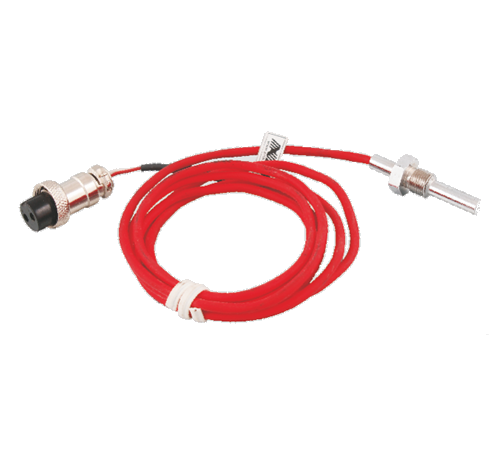

By connecting the PT100 thermal sensors to the slot that is standardly placed on upper bearing body, motor temperature values can be easily measured.

By connecting the PT100 thermal sensors to the slot that is standardly placed on upper bearing body, motor temperature values can be easily measured. Slinger helps to prevent the sand inside the water of the well entering in mechanical seal and through mechanical seal to inside of the motor.

Slinger helps to prevent the sand inside the water of the well entering in mechanical seal and through mechanical seal to inside of the motor. Chrome-plated and precisely machined bearing collets which are located in the radial bearings operating area, have great importance for bearingthe rotor.

Chrome-plated and precisely machined bearing collets which are located in the radial bearings operating area, have great importance for bearingthe rotor. Radial carbon bearings, which have channels in its structure that makes it possible to get lubricated by water easily, provides precise bearing of rotor shaft at upand down.

Radial carbon bearings, which have channels in its structure that makes it possible to get lubricated by water easily, provides precise bearing of rotor shaft at upand down. It rules the pressure changes in water excellently check valve balances inner pressure, by throwing out and gettin in after filtering the water, dependently to changing pressure. So it prevents the membrane from pressure explosion.

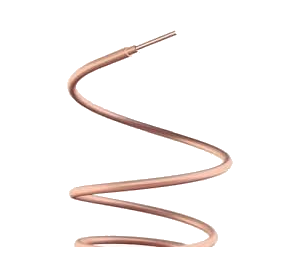

It rules the pressure changes in water excellently check valve balances inner pressure, by throwing out and gettin in after filtering the water, dependently to changing pressure. So it prevents the membrane from pressure explosion. PE2+PA coil wire allows the engine to run at 70°C well temperature. Increases the life and durability of the submersible motor.

PE2+PA coil wire allows the engine to run at 70°C well temperature. Increases the life and durability of the submersible motor. Provides safe operation conditions for motor by absorbing Up-Thrust loads with it's machined surface and water channels on it.

Provides safe operation conditions for motor by absorbing Up-Thrust loads with it's machined surface and water channels on it. Rotor shaft, top side is made of AISI 304 material. Shaft end connection in NEMA Standards.

Rotor shaft, top side is made of AISI 304 material. Shaft end connection in NEMA Standards.