Phone

Mat stainless steel pump series are designed by Mat engineers using Computaional Fluid Dynamics (CFD) methods. With its modern design, high efficiency and low energy consumption, as well as high quality materials, it ensures the pumps to have long life and high durability In our company, within In our company, within range of products;

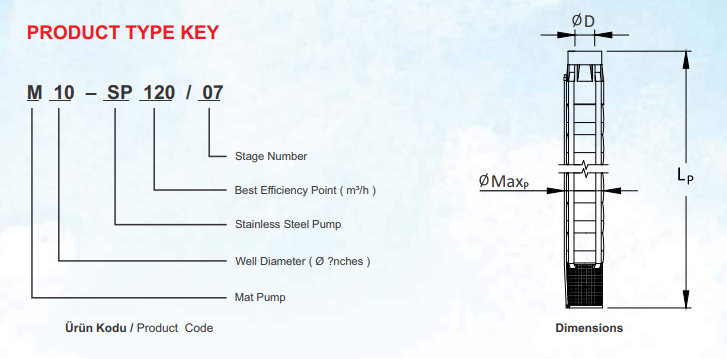

• 4",6'',8'' and 10" types,

• From 0 to 300 m³/h capacity range,

• At 50 Hz (2900 rpm ) and 60 Hz (3450 rpm)

frequencies and speeds,

• The production of clean water pumps operating at a maximum head of 600 m is made.

All pumps before shipment; they were subjected to the necessary tests according to the definitions of the standards

In the products; “Superior Technology and Low Energy Consumption” are given importance.

WORKING CONDITIONS

• Clean and nonabrasive liquids

• Maximum water temperature 40 °C (Optional water temperature 70 °C)

• Liquids with a maximum sand amount of 50 g/m³

USAGE AREAS

• Municipal water supply and distribution

• Municipal water treatment

• Domestic water supply

• Irrigation in horticulture and agriculture

• Industrial applications

• Pools, fountains, etc.

• Pressure boosting

• Greenhouse and nurseries

• Food industry

ADVANTAGES

• Wide range of sizes

• High efficiency

• Low energy consumption

• State-of-the-art hydraulics design

• Long life

• High durability

• Light in weight

• Smooth surfaces

• Easy installation and service opportunities

• Wear-resistant design

• 100% high-grade stainless steel (AISI 304)

• Suction and outlet chambers single piece special precision casting

• Water lubricated bearing

• Check valve to prevent backflow of water

• Motor connection in TS 11146 and NEMA MG1 standards

M4-SP2

M4-SP3

M4-SP4

M4-SP8

M4-SP12

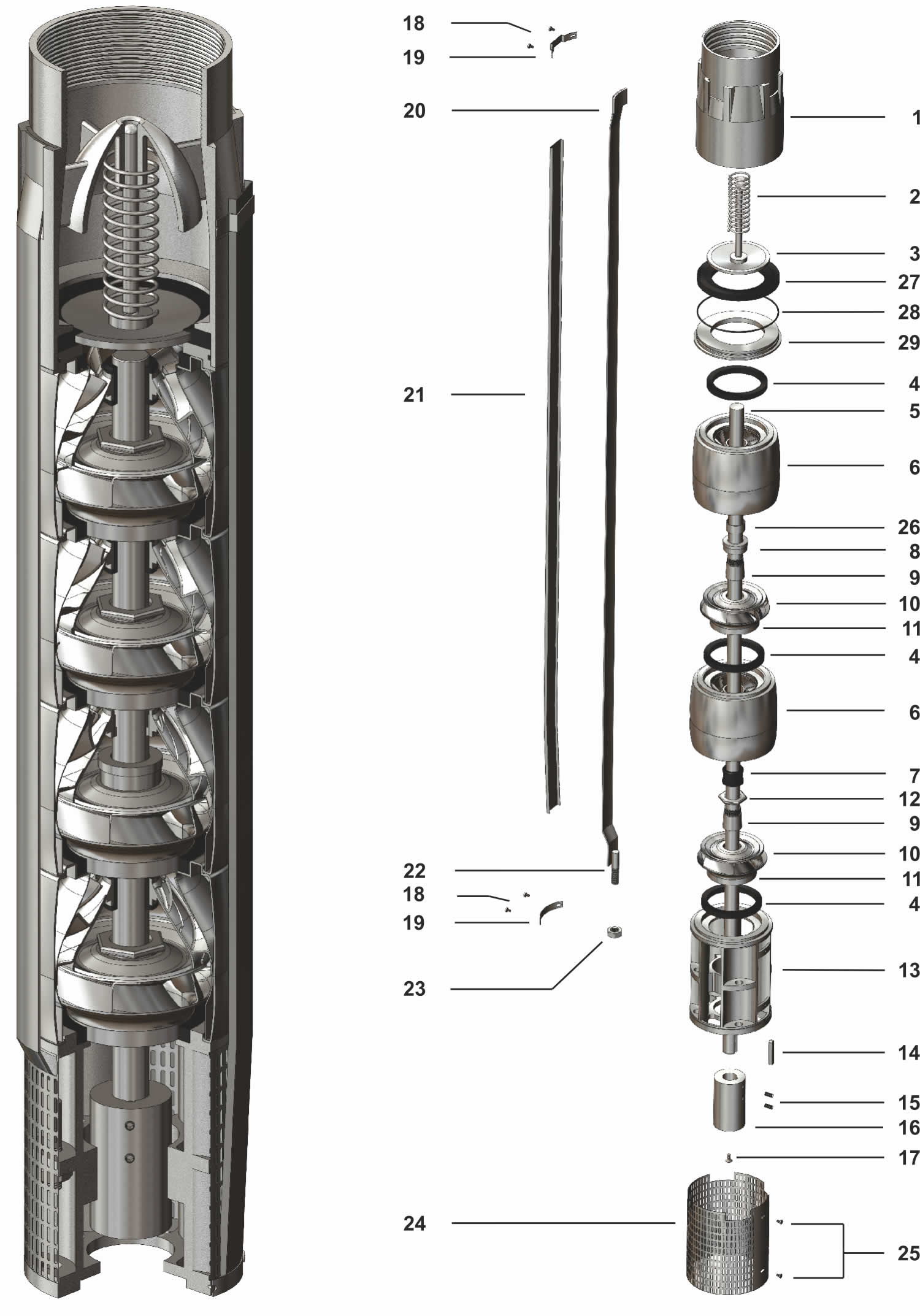

| Part Name | Material | |

|---|---|---|

| 1 | Valve Casing | AISI 304 |

| 2 | Valve Spring | AISI 302 |

| 3 | Valve Cone | AISI 304 |

| 4 | Neck Ring | RUBBER (NBR) + STEEL |

| 5 | Shaft | AISI 420 |

| 6 | Diffuser | AISI 304 |

| 7 | Diffuser Bearing with Sand Channels | RUBBER (NBR) |

| 8 | Nut for Stop Ring | AISI 304 |

| 9 | Split Cone | AISI 304 |

| 10 | Impeller | AISI 304 |

| 11 | Impeller Wear Ring | AISI 304 |

| 12 | Split Cone Locknut | AISI 304 |

| 13 | Suction Case | AISI 304 |

| 14 | Shaft Key | AISI 304 |

| 15 | Grub Screws | AISI 304 |

| 16 | Coupling | AISI 420 |

| 17 | Coupling Screw | AISI 304 |

| 18 | Cable Guard Screws | AISI 304 |

| 19 | Cable Guard Tie | AISI 304 |

| 20 | Strap | AISI 304 |

| 21 | Cable Guard | AISI 304 |

| 22 | Strap Stud | AISI 304 |

| 23 | Strap Nut | AISI 304 |

| 24 | Strainer | AISI 304 |

| 25 | Strainer Screws | AISI 304 |

| 26 | Stop Ring | AISI 304 |

| 27 | Valve Seat | RUBBER (NBR) + STEEL |

| 28 | Klinger Gasket | PAPER |

| 29 | Valve Ring | AISI 304 |